1. Introduction

Since 2006, Artificial Intelligence (AI) has attracted our attention a lot, and nowadays, its heat is still there, playing an active and important role in our daily life. It is believed that the appearance of Artificial Intelligence is the dawn of the 4th Industrial Revolution (4IR). Of course, there are some arguments that AI technologies might lead to an increase in the unemployment rate, much more inequality in many different aspects, and so on. However, the fact of increasing productivity and decreasing unemployment from the previous industrial revolutions should give us faith in AI.

In section 2, we are going to discuss why AI is the most important factor contributing to the 4th Industrial Revolution. There will be five trends explained to support our opinion. What is more, some refutation of cons will be discussed in section 3. The last part is our conclusion for this opinion article.

2. Tech-trends of AI that affect the 4IR

2.1. Ubiquitous Computing

With the rapid development of technologies, for example, computer microchips have become much more powerful but smaller in size than before, the smart devices permeate into almost every field of our daily lives, including the industry. These smart devices do not only refer to the computer but everything. More accurately, a “ubiquitous world” indicates an environment with integrated networks; a computer integrated manufacturing system (CIMS), and invisible computers with sensor microchips equipped and radio frequency identification systems. In this environment, the new information and technologies for communication make the cooperative work that is supported by computers transform from remotely to ubiquitously.

The last era is about mobile computing, we can easily know this from the widespread use of smartphones and laptops. But this era is about ubiquitous computing, not only can the computer be smart, but every device, even object. Ubiquitous computing reduces the limitations on the workplace and requires less human interaction because of information sharing among the devices, the capabilities of manufacturing are enhanced. There is a nice example, the Internet of Things or IoT (which will be talked about more in the next subsection) enables communication among devices, objects, and computers, and accelerates the speed of production.

2.2. Cyber-Physical Systems (CPS) and the Internet of Things (IoT)

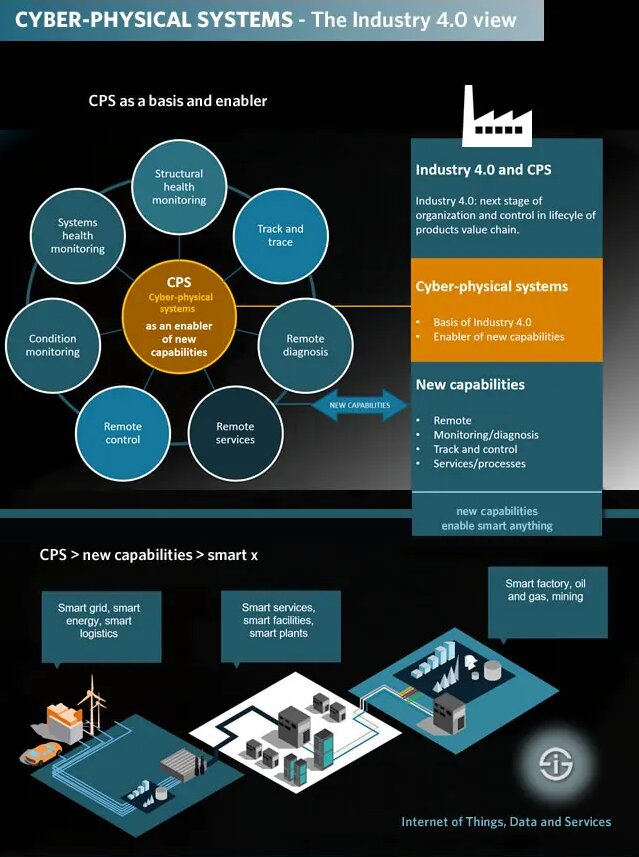

Cyber-physical systems (CPS) are the foundation of the 4th Industrial Revolution. They have some embedded software systems and deal with an Internet address in order to be addressed and have a link to each other through IoT or the Internet of Things. In this complex context, modern control systems are the commanders among them. The reason why CPS are essential is that it enables the products and the approaches of production to communicate with each other, generating new means of production and optimizing in real-time. In a word, thanks to CPS, the industrial systems are networked and have a huge improvement in the capability of data exchange. As a result, the possibilities of current manufacturing are enlarged. For instance, areas like structural health monitoring, track and trace, and remote services have new possibilities due to CPS.

Moreover, CPS are inseparable from industrial IoT, CPS are the bridging of the physical and digital world of industrial IoT. We have mentioned several times the term “IoT” above, but you may have already heard about it many times from other places. The IoT stands for the Internet of Things, it means the connections between many physical devices and objects that are embedded with sensors, software, and some other technologies, which enables the networked system to communicate in a way of exchanging data directly and be intelligent.

Actually, cyber-physical systems and the Internet of Things are very similar, CPS will not be there without industrial IoT. Let’s look at the key characteristics of CPS and compare it with the Industrial IoT.

- Cyber-physical systems are seen as the next evolution in the industry.

With the help of Internet technology, and the connection of Information Technology (IT) between Operational Technology (OT), CPS work as the bridging of the cyber and physical world. It is this bridging that accelerates the process of the Industrial Revolution. In this process, the Industrial IoT is the enabler of CPS, in other words, the process cannot proceed without the help of IoT, both of them are vital to the 4th Industrial Revolution.

- Cyber-physical systems are able to communicate.

They are controlled by modern and smart control systems, having embedded software and other essential components, therefore, they have the ability to “communicate”, not speaking like a human, but exchanging data among the network they formed. Both CPS and IoT are essentially connected objects, in order to share and update data in a more efficient way, in this case, they have the ability to communicate.

- Cyber-physical systems are unique from each other.

Each system in CPS has a unique identifier, also known as IP (Internet Protocol) address. This address enables the system to be traced easily and communicate efficiently. In the meantime, the IP address is also the key feature of IoT.

- Cyber-physical systems consist of controllers, sensors, and actuators.

These three elements have already existed in the previous Industrial Revolution, but they are becoming more important in this stage, as they also play a significant role in IoT or the Internet of Things.

- Cyber-physical systems enhance the capabilities of smart factories, smart logistics, as well as other smart areas.

The capabilities needed by the smart areas of applications are known as remote control, remote monitoring, track and trace, and so forth. These capabilities enabled by CPS are also the use cases of IoT.

2.3. Autonomous Robots

The third Industrial Revolution, also called Digital Revolution, is about the spread of automation and digitization in a way of making use of computers and other electronics. However, there will be much more automation developments during the 4th Industrial Revolution. As we mentioned before, the IoT will be the power of this autonomous production as it connects the objects, devices, and computers machines together, enabling real-time communication among them. Not only are the production processes autonomous, but the autonomous robots will play a significant role in manufacturing. There are four main reasons why it became the trend towards the 4th Industrial Revolution.

- Improving Productivity

As we all know, productivity has been improved once and once again in the previous industrial revolutions. It makes sense, the technologies are developing, and now, the same case holds, the rapid development of artificial intelligence technologies will enhance productivity once again, it is expected to increase by up to 40% by 2035.

Some may say that autonomous robots will make a lot of workers lose their jobs, however, according to some research, the use of AI may generate more job opportunities, enabling the employees to find a new job.

- Decreasing overhead costs

Although the initial investment might be huge, the return will cover it soon. For example, the cost of salary could be saved since some of the human workers are replaced by machines; the cost on healthcare and safety could be reduced; moreover, the factories could invest less money on the revenue because some robots are smaller in size but more powerful than human beings.

- Reducing human error

Making an error cannot be avoided, but the possibility can be reduced. Computers are better than human beings when it comes to this issue, at least a well-programmed computer will be. With studying from a big data pool based on their embedded algorithm, an AI robot could always make an accurate decision to finish the work assigned to it.

- Minimizing the human input

Connected to an intelligent controller which contains a central server, database, or logic controller, the actions of these robots are more consistent and automated than before, acting intelligently. There will be as little human input as possible during the production process since they can make intelligent decisions by keeping the information updated in real-time.

2.4. Big Data

IoT(Internet of Things) and ubiquitous computing are contributing to the large volume of data which are generated from people’s daily lives. These tons of data not only come from human’s daily lives, but also from machines’ uses. In the era of digitization, there is going to be more and more data available for industrialists to analyze. Manufacturers can utilize this data to design customized products and services, upgrade business processes, enhance decision-making processes, and improve manufacturers’ yearly revenues.

In the 4th Industrial Revolution, big data analysis performs a central role in the area of smart factories. Big data of AI will tremendously contribute to manufacturers’ and industrialists’ smart warehousing process. Manufacturers can use sensors, barcodes, portable devices to improve the efficiency of operation and warehousing logistics. For example, by using big data analysis of AI, manufacturers can maintain a relatively low level of inventory by using AI predictive demand. Predictive demand methods can make much more accurate and rapid predictions of customers’ demand trends by analyzing big data of consumers’ behavior. Big data of AI also can accurately identify predictive inventory levels by correlating predictive demand trends and necessary level inventory maintenance optimization. Datafication can also identify variables that can improve warehousing performance at relatively low cost, have manufacturers identify warehousing problems and bottlenecks, and also have the optimization of predictive maintenance.

Big data analytics of AI plays another critical role in terms of automated production management by using AI technologies of smart sensors through cloud computing and IoT(Internet of Things) platforms that will discover patterns to help manufacturers to improve the efficiency of production management and supply chain integration. In this way, it saves a tremendous amount of human labor. Automated production works by analyzing historical data of production process added with information from the real-time production process and automated equipment featured by manufacturing robotics and actuators which are connected to manufacturing control software. Big data analytics of control software can signal targeted commands to manufacturing robots and actuators which will change settings of pieces of machinery for automated productions without human interventions.

2.5. Augmented Reality and Virtual Reality

Augmented reality is one of the most promising applications in the field of the industrial revolution. Manufacturers are improving production processes with higher efficiency by utilizing Augmented Reality applications. In the first place, Smart factories are applying data accessibility of AR to speed up industrial operations, increase production process efficiency, and reduce error occurrence. In the second place, Augmented Reality and Virtual Reality allow empowering the workforce and train operators to be more efficient in increasingly complex production processes. Augmented Reality in industry 4.0 can support working technicians in their real-time working situation by remote assistance systems to visualize step-by-step procedure of the task to be performed or even get visual instructions in real-time from experts. Thirdly, Virtual Reality technology can have simulations of productions, operation processes are engineered in the first person and in an immersive way. It has great applications in terms of designing engineering products in a much more visual and interactive way through a visual simulation. Virtual Reality can also enable training in complex or dangerous tasks before having to perform them in a real situation, avoiding any associated risk and obtaining cost savings for companies. It can also help to provide personalized and autonomous training for technicians and optimize the learning processes in industry 4.0. In addition to the above, AR and VR can enable plant maintenance and control, incident assistance and resolution, minimized downtime, increased safety and cost savings during manufacturing processes.

3. Potential Negative Aspects, Challenges and Recommendations

There are some potentially negative aspects of Artificial Intelligence in terms of the 4th Industrial Revolution. Cybersecurity is the major concern for manufacturers during manufacturing and business processes. There are the following challenges of cybersecurity in the age of industry 4.0. For Instance, devices connected to manufacturing systems of Industrial Control Systems(ICS) have potential risks of cyberattacks. In the 4th Industrial Revolution, systems are all interconnected so that there is a bigger surface for potential cyber-attack and industry had fewer regulations of cyber-security than other sectors.

Although there are challenges above, there are definitely more solutions to solve the challenges. Manufacturers should have a risk-management of cyber-security mindset to defend against different types of cyber-risk so that they keep a certain good level of inventory and combine IT and OT together as a defense strategy. The solution is also to find out systems which are outdated and have them upgraded and have technology suppliers and equipment manufacturers audit the software of connected systems regularly by using a security-first approach. By using all these measures and protecting practices, we believe that there is a good chance to defend against cyber-attacks for manufacturing processes in the 4th Industrial Revolution.

4. Conclusion

In short, the rapid development of Artificial Intelligent technologies gives a context for the 4th Industrial Revolution. The interesting thing is that history is repeated, there is some fear among the people, just like it was in the previous industrial revolutions. We know that people opposed the first industrial revolution and there was a public reset because of the fear of the possibility of unemployment and even the crumble of society. Nevertheless, the consequences of the revolution are more on the positive side. We can learn a good lesson from history. Development and progress are essential and we should not only focus on the unknown and even the possible negative parts. Instead, we should have a risk-management plan as a backup. Governments can put some advertisements on the positive effects of AI technologies, and also set rules for regulating the new technologies in order to reduce the possible drawbacks it might bring to society. The manufacturer should have a good plan for the operation of the factory so that a quick reaction can be taken when the revolution occurs. Workers should keep learning in order to not be the redundant one who is going to be replaced by the robot. As for scientists, especially AI experts like us, our tasks are doing more research and making analyses to give suggestions or possible solutions to the public.